| coated calcium carbonate | SFC-01C | SFC-02C | SFC-03C | SFC-04C | SFC-05C | SFC-06C | SFC-07C | |

|---|---|---|---|---|---|---|---|---|

| Chemical Analysis | CaCO3(%) | 94-95% | 95-96% | 95-96% | 96-97% | 97-98% | 97-98% | 97-98% |

| CaO(%) | 52-53% | 53-54% | 53-54% | 54-55% | 55-56% | 55-56% | 55-56% | |

| MgCo3(%) | <2.50% | <2.00% | <2.00% | <2.00% | <2.00% | <2.00% | <2.00% | |

| MgO(%) | <1.80% | <1.50% | <1.50% | <1.50% | <1.50% | <1.50% | <1.50% | |

| SiO2(%) | <2.00% | <1.50% | <1.50% | <1.50% | <1.50% | <1.50% | <1.50% | |

| Fe2O3(%) | <0.07% | <0.07% | <0.07% | <0.07% | <0.07% | <0.07% | <0.07% | |

| Al2O3(%) | <0.08% | <0.08% | <0.08% | <0.08% | <0.08% | <0.08% | <0.08% | |

| Hcl Insoluble | <0.05% | <0.05% | <0.05% | <0.05% | <0.05% | <0.05% | <0.05% | |

| Physical Properties | Mean size D50 | 5.2 micron | 4.5 micron | 3.7 micron | 2.8 micron | 2 micron | 1.7 micron | 1.5 micron |

| Top cut size D97 | 20 micron | 15 micron | 12 micron | 10 micron | 8 micron | 6 micron | 5 micron | |

| Mesh | 750 | 1000 | 1250 | 1500 | 1875 | 2500 | 3000 | |

| Whiteness | 97 | 98 | 98 | 98 | 98 | 98 | 98 | |

| Brightness | 96 | 96.5 | 96.5 | 96.5 | 96.5 | 96.5 | 96.5 | |

| pH value | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | |

| Residue on 325 Mesh | ||||||||

| Density kg/m3 | 970 kg/m3 | 900 kg/m3 | 870 kg/m3 | 830 kg/m3 | 780 kg/m3 | |||

| hardness | 3mohs | 3mohs | 3mohs | 3mohs | 3mohs | 3mohs | 3mohs | |

| Stearic Acid coating for coated calcium carbonate powder | Coating:- 1% | |||||||

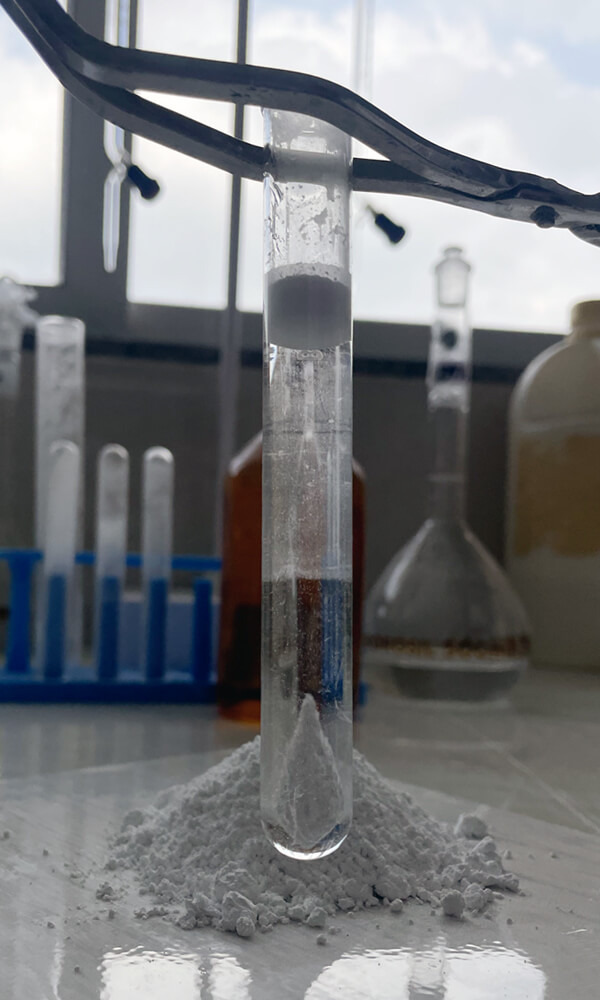

Indigenous Coated Calcium Carbonate (CCC) is a specialized, surface-treated form of natural calcium carbonate (CaCO₃), designed to improve compatibility with various industrial matrices such as polymers, plastics, and rubber. SFC Chemicals Pvt. Ltd. supplies high-performance coated calcium carbonate with enhanced surface properties, making it ideal for high-end applications that demand better dispersion, strength, and durability.

SFC Chemical Pvt. Ltd. ensures each batch of coated calcium carbonate is developed to meet strict industry standards. Our advanced coating process and selection of high-purity base minerals make our product a reliable choice for manufacturers.

Surface Modification with Stearic Acid: Coated with high-quality fatty acids for improved compatibility with hydrophobic systems like plastics and rubber.

Superior Dispersion: Ensures uniform distribution in non-polar compounds, reducing clumping and enhancing end-product quality.

Improved Mechanical Properties: Increases tensile strength, impact resistance, and overall performance in filled polymer systems.

Reduced Processing Time: Enhances processing efficiency during extrusion, molding, or compounding.

Moisture Resistance: Coating provides better resistance to humidity, extending shelf life and stability.

Customizable Grades: Available in tailored particle sizes and coating levels to suit specific application needs.

SFC Chemical Pvt. Ltd. SFC Chemicals Pvt. Ltd. is a reputed supplier of coated calcium carbonate, committed to innovation, consistency, and sustainability. Here’s what sets us apart:

In-House Coating Technology: Precision-controlled processes to ensure consistent coating thickness and surface properties.

Strict Quality Control: Each batch undergoes rigorous lab testing to meet global quality benchmarks.

Application-Specific Grades: From masterbatches to profiles, we cater to industry-specific requirements with precision.

Efficient Logistics: Our supply chain is optimized for prompt delivery across domestic and international markets.

Sustainable Manufacturing: Our processes are designed to minimize environmental impact while delivering superior performance.

Coated Calcium Carbonate is indispensable across various industrial applications where performance, consistency, and compatibility are critical

Plastic Industry: Used as a functional filler in PP, PE, PVC, and other thermoplastics to reduce cost and improve dimensional stability.

Rubber Compounding: Enhances mechanical properties and reduces oil absorption, leading to stronger, more durable rubber products.

Masterbatches and Compounds: Improves flow properties and ensures high filler loading without compromising product integrity.

Paints & Coatings: Enhances weather resistance, gloss, and opacity in solvent-based systems.

Adhesives & Sealants: Improves bonding strength and rheology without affecting curing properties.